GTX Engineering and Construction Co., Ltd

The company's business covers the construction of high-tech plant projects focusing on pharmaceutical, electronics and specialty chemical industries, and its cooperative clients are mostly large multinational corporations, including Coca Cola, Corning, Johnson Controls, Celanese, BASF, Eli Lilly and Novartis, etc., with a total constructed project area exceeding 1 million square meters.

Key Milestones:

In April 2007, the company was registered with 20 million CNY. Cooperated with other teams to launch the Wuhan Coca-Cola Bottling Line Project and the Owens Corning Hangzhou Factory Project.

In 2013, the company made business presence in cold-chain logistics, fine chemicals and pharmaceutical industries, shaping a new pattern of operations. It successively constructed such high-end projects as Swire American-Style Cold Storage, Zhuhai Bimei Specialty Chemicals Plant, and Eli Lilly Suzhou Plant.

In 2017, the company got aligned to China’s national strategies and opened up a business channel to the electronics industry. It constructed the Corning LCD Glass Substrate Facility in Hefei, a data center in Hangzhou and JHICC DRAM production line project, and established an independent company.

In 2021, the company was awarded the Grade A EPC Certificate for Buildings, further expanding its business portfolio.

In 2024,the company positions Singapore as the core hub and realizes the interconnected development of the Southeast Asian market through equity control, business empowerment, and resource integration.

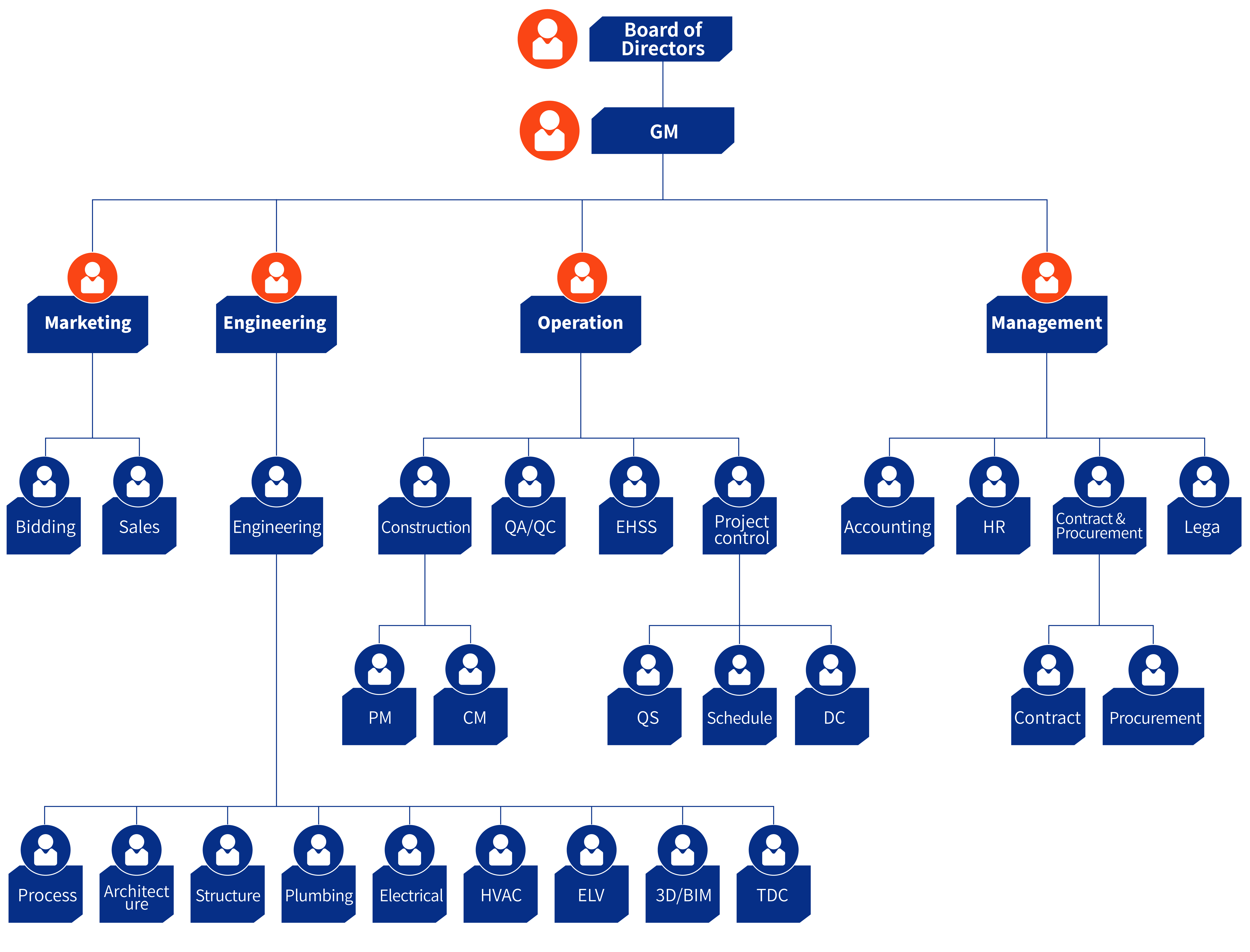

Our Organization

Our Services

- Engineering Consulting

- We have over 20 years of profound hands-on experience in serving Global Fortune 500 companies. We excel in providing engineering process management, cost consulting and project implementation consulting services.

- Procurement

- We are good at mining and analyzing customer needs. Trust is the cornerstone of business transparency, and also the most important and time-efficient way to reach business cooperation. Through quotation analysis, supply chain integration and complementary strengths, you can identify the most suitable team and products.

- Project Construction

- Customer satisfaction is our top priority, and our people collaboratively work to meet customers’ targets. Our Project Support Center provides strong supports. Passion, dedication and expertise make the underlying logic that ensures your project success.

- Digitization

- Digital tools are used in the installation link to create visual building information model. In the early stage of construction, the conflicting issues between all disciplines are coordinated to make complex projects simple, and the principle of “Do It Right The First Time” is implemented to reduce the rework related waste of time and resources. In this way, significant cost saving benefits can be delivered.

- Prefabrication

- The use of prefabricated modules greatly enhances resource utilization rate and reduces costs. By building in-depth partnership with many prefabrication factories in China and the outside world, we can perfectly meet the non-standard customization requirements of customers.

- Operation & Maintenance

- Our professional Operation & Maintenance team provides all-round operation and maintenance services for customers’ excellent projects. We have been working to improve our professional services and help customers achieve worry-free production, increase product yield and lower operation and maintenance costs.

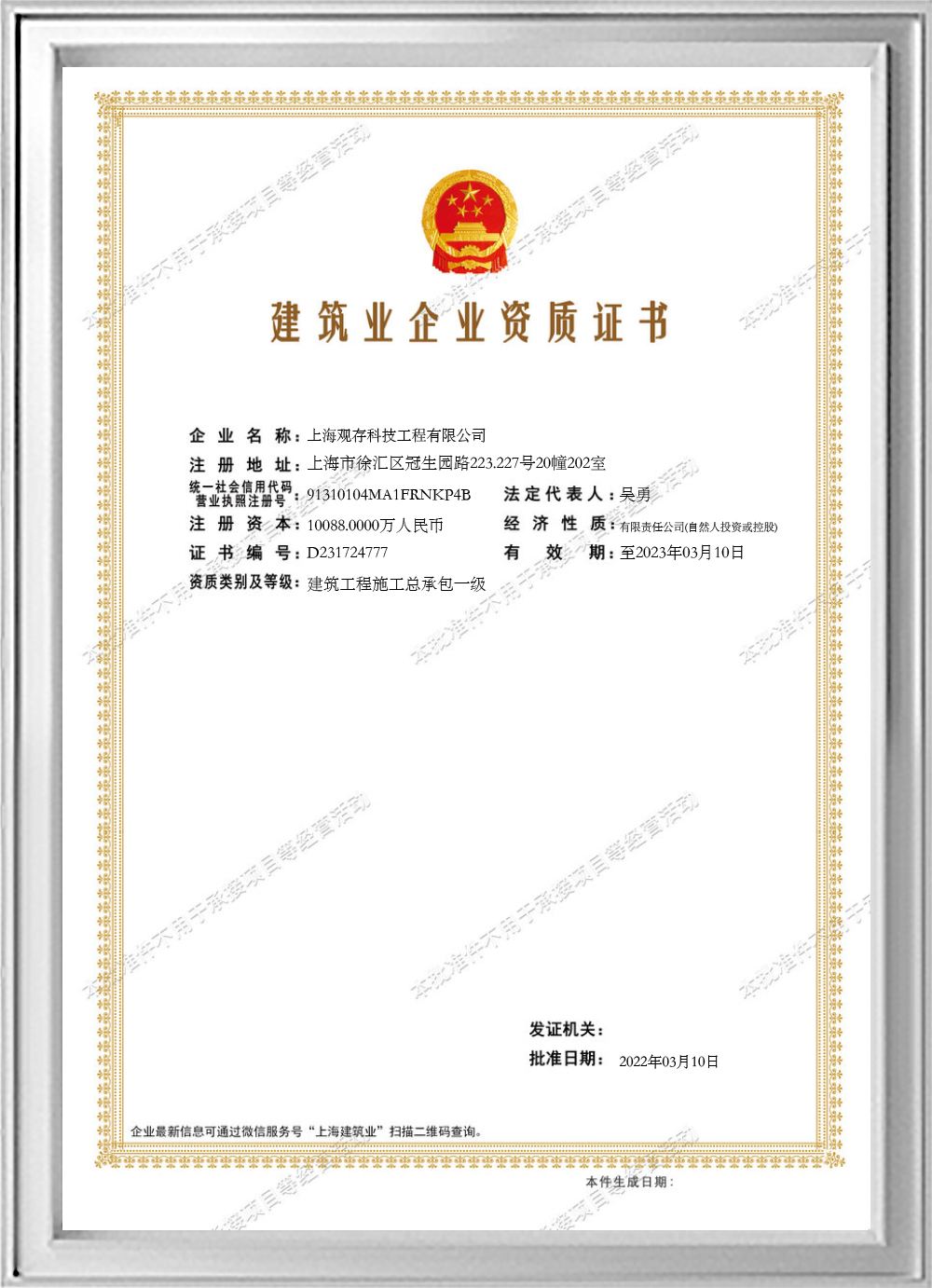

Qualifications

Qualifications